DC Cryo-Cooler

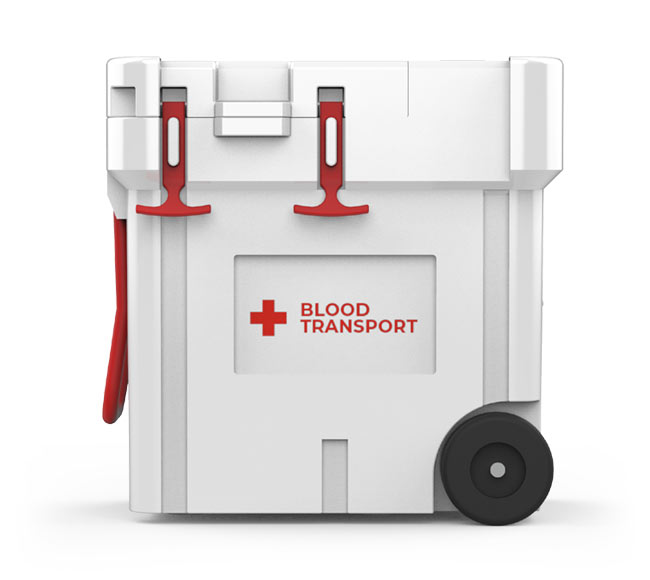

Motivated by change, the DC Cryo-Cooler powerfully executes a robust and safer portable freezer solution to the cold logistic industry.

With a temperature range of 30 degrees down to minus 80 degrees and a DC battery life ranging from 24 hours to 72 hours—the DC Cryo-Cooler—will fundamentally change the market, offering a solution that will maintain effectiveness and long-term viability.

FEATURES

Logistical Flexibility

The DC Cryo-Cooler can offer users efficient, reliable, low temperature cooling down to-80°C under any travel conditions. The DC Cryo-Cooler can be used for transport via air, road or sea with no limitations on timeframes or weather. The structural design along with added safety measures, means the integrity of the contents remain intact and can even be used as a storage unit at the destination in the event they do not have appropriate medical equipment.

Energy Savings

Stirling technology uses 70-75% less energy than other standard compressor-based freezers. Harnessing this technology allows us to deliver an efficient cooling process that directly translates into immediate savings in energy consumption and reduces operating costs over the freezer’s lifetime.

Intelligent Temperature Control

The DC Cryo-Cooler has a digital display screen that is high-definition and back-lit to provide clear user visibility. The interface is easy to use with simple and straightforward operating functions. The Inner temperature probes have an accuracy of 0.1°C and the unit can be easily set to temperatures between 0°C and -85°C. High density EVA blind hole foaming is used for insulation, which allows greater heat preservation flexibility and shape.

Flexible & Reliable Power Supply

With input power of 80 watts, the DC Cryo-Cooler can be reliably

operated using either DC 12-24 volts or AC 110-240 volts. This flexibility allows users to safely transport blood and other materials, with multiple options for power supply and ensures safe temperatures are maintained.

Low Maintenance

Stirling coolers require minimal to almost no maintenance at all, and the system is oil-free which eliminates the risk of leaks. This makes taking care of the portable freezer even easier. The portable freezers have been designed for durability and repeated use over many years,

without the need laborious or costly maintenance schedules.

Cryo-Cooler Technology

Just as an electric motor can be used in reverse as a generator, energy can be placed into a Stirling engine and run backwards, effectively removing the heat and expelling it at the source. This process turns a Stirling engine into a “cryocooler” — a very efficient cooling device.

-80oC

No more wasted

products with

Cryo-cooling.

OTHER APPLICATIONS

Biotech & Pharmaceutical

The low temperatures can be used for maintaining chemicals and other pharmaceutical products. Freeze drying, preventing by-product formation, and even cryo preservation are also potential uses of the DC Cryo-Cooler.

Energy & Chemical

The chamber can create a cryogenic environment for users to analyse and inspect different chemicals. The internal environment created by the DC Cryo-Cooler technology can also be used to test reactions of chemicals.

Metrology

Where users need to maintain precise temperatures and keep it at the desired low levels, this unit is perfect given it’s easy system operation an accuracy of the probes and sensors.

Food & Logistics

Chambers used to separate contents from direct cooling can be customized to retain temperatures required for most food deliveries to ensure its freshness.

Medicines

The low temperatures that the DC Cryo-Cooler can reach combined with the flexible power supply options and huge energy savings means it is a viable option in the place of a standard medical freezer.

Specifications

Internal Dimensions

1.8L or 10L internal volume options; temperature control accuracy ± 2°C; ultra-low temperature controlled mobile safe, with adjustable

temperature range from -80°C to 30°C. Used to transport biological

samples such as vaccines, bacterial viruses, blood, human organs,

immune medical products and other goods that have extremely sensitive temperature requirements.

Specification Chart

What can the DC Cryo-Cooler do for you?

Current logistical strategies are reliant on either dry ice being used throughout the entire journey, often needing a ‘top-up’ during travel, or by using specialized vehicles with built-in generator systems. These current cold chain problems will mean wasted and unusable deliveries if they continue to be used.